Areas of Usage

Military buildings, public authorities buildings, psych wards, jewelers, banks, police stations and museums.

Click for the Table New Technology Multi Later Security Glass and the Table of Polycarbonate

Compounds

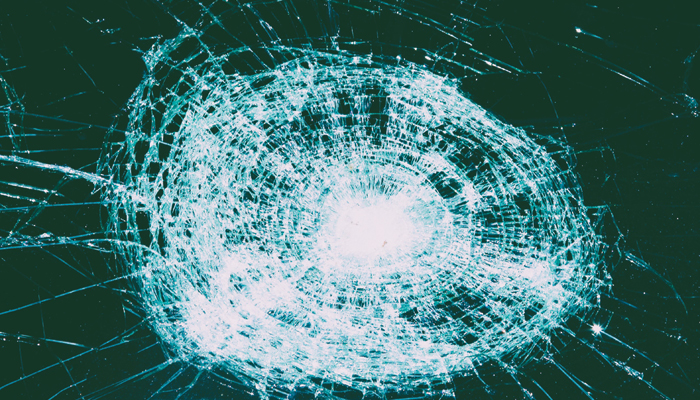

Full tempering increases the strength and resistance of glass against thermal stresses. Tempering procedures at Ardıç Glass contains the stages of heating and cooling to bring compression stress to the outer surfaces and, tensile stress to the middle part of the glass on a horizontal line. Tempered glass that is durable 5 times non heat-treated glass is shattered into parts in the size of a dice reducing the risk of injury, and this is why it is used as security glass.

Heat treatments do not change the volume, chemical structure, color and transparency of the products. Colorless float, colored float and laminated glass (before lamination) and coated glass may be subjected to heat treatment. After the heat treatment, the glass board is not subjected to any cutting, drilling, edge and surface treatment.

However, there are some “distortions” as an inevitable and unavoidable result of a heat treatment on the condition that “tempering marks” and “humps” and “extraversions” that could be only noticeable under certain light conditions are within the respective tolerances. These marks that are minimized by means of the application of a sensitive heating regime during the tempering procedure are not considered defects.

Even if it is rare, tempered glass may be subjected to a pre-elimination through a heat soaking whenever required in case of spontaneous breakage due to microscopic particles that may arise due to some certain production methods for frits. Tempered glass is manufactured in line with the Standard for Soda-Lime-Silicate Security Glass thermally tempered that are used for glass structures per TS EN 12150.